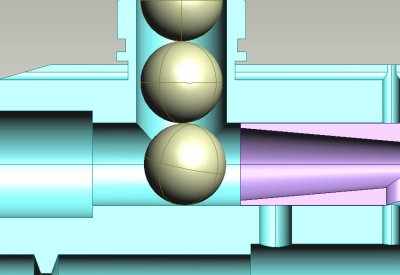

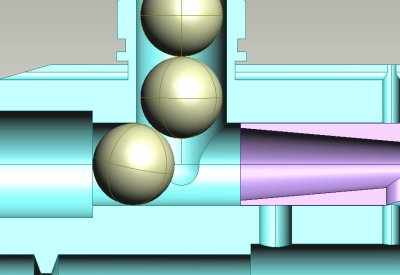

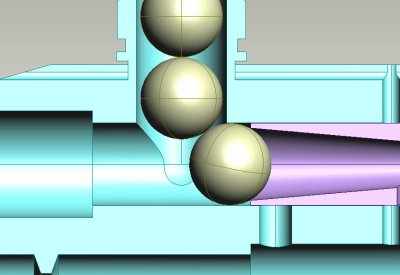

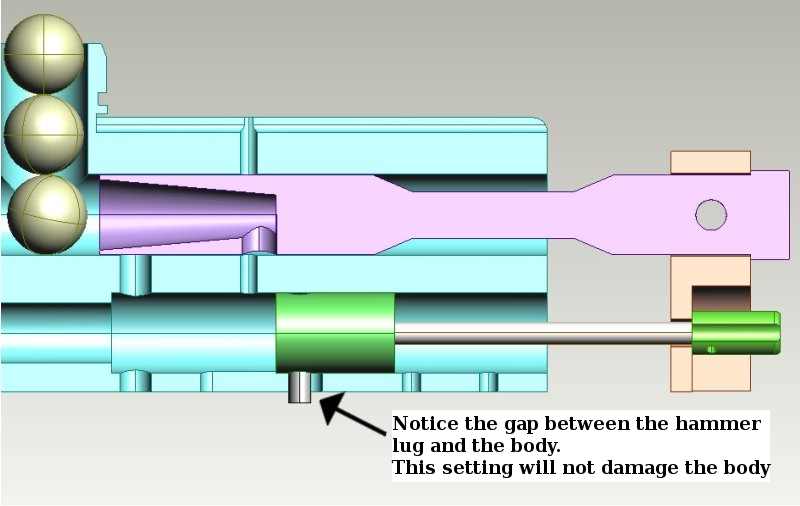

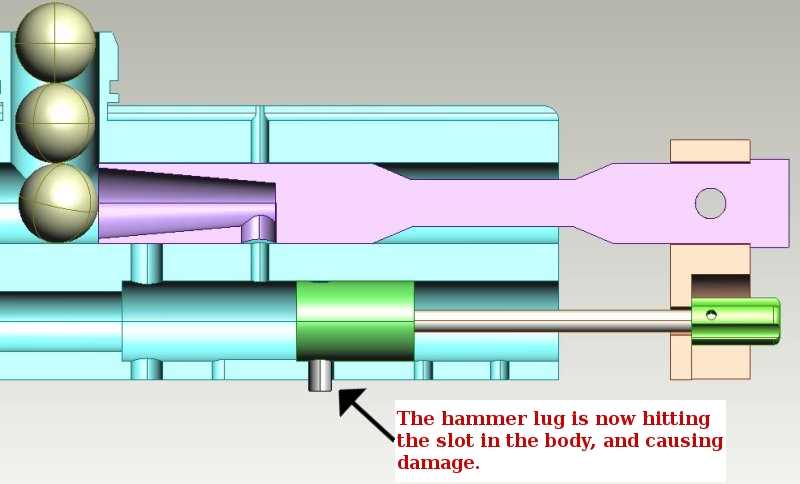

How to Correctly Set Your Cocking Rod LengthAnd how to do it without damaging your body. OK, this has been going back and forth for a while now. At some point, someone decided that using the cocking rod to limit the travel of the back block was a good idea. It isn't. First, we are going to cover why bolt position doesn't matter on an electro cocker, then we are going to cover why you shouldn't try to use the cocking rod to control the bolt location. Now, over the last few years, there have been guns that had problems with force feed loaders, like the Halo, over powering the ball detentes, and forcing two balls into the breach, or a ball and a half into the breach. The first picture is the ideal setup for an open bolt gun. The ball in the breach is centered in the feed tube, and doesn't allow the next ball in the stack to protrude into the breach.  Here we see what happens when the ball in the breach rolls forward past the ball detentes, or back against the bolt. The second ball is either going to load into the breach by pushing the first ball into the barrel, or the bottom edge of the second ball will stick into the breach, and get a nice hit from the bolt as it comes forward. Again, either one can break paint in the breach or feed tube.   The solution to this is to place the face of the bolt so it will hold the ball in the breach directly in line with the ball stack. That directs all the force of the loader pushing on the ball stack at the bottom of the breach. By directing the force down, the ball won't be pushed forward by the next ball in the stack. To do this on a Timmy, they came out with adjustable end caps. Other open bolt guns either use the same type of rear travel limit, or have an adjustable length bolt. So, a cocker is no different, right? Wrong. On an open bolt gun, the bolt stays back until the gun fires, allowing ample time for one and a half, or two balls to load into the breach. The cocker isn't an open bolt gun. As soon as the breach on an electro cocker opens, and the ball feeds in, the bolt is closing. There isn't enough time to feed more than a ball in to the breach. The stock delay between the eye detecting a ball, and the bolt closing on an E-Blade is 1 millisecond. You are not going to get a ball to shift forward, and allow another ball even part way into the breach in a single millisecond. I know, I have tried over and over before I wrote this article, just to make sure. I even tried it with a mechanical cocker, holding the trigger back after each shot. The only time I was able to get the ball in the breach to roll forward any appreciable amount was when I shook the gun violently as if I was running. The simple fact of the matter is that unless you are trying to get more than one ball into the breach of a cocker, or any other closed bolt semi for that matter, it isn't going to happen. So, why are people so concerned with bolt location on a cocker? Beats the hell out of me. I think it's followers logic, and nothing more. You know the "Well, if they have to worry about it, it must be an issue for me also" thinking. The thing is, I have yet to see a case where a properly timed gun will allow a second ball into the breach on a cocker. I have seen cases where the Reloader B was set with so much tension that every time they use any type of decent tourney paint, the ball being loaded was slammed into the breach hard enough to crack the shell though, and he was more than happy to blame it on the bolt position until it was fixed by using a sane feed setting, and showing him a cracked ball when the gun was in classic mode, and not allowed to close the bolt. He shut up once he was shown the balls were breaking going INTO the breach, and not being broken when the bolt was closing the breach. In this picture, you see the correct way to set a cocker's back block, and cocking rod. The cocking rod is pulling the hammer back far enough to ride over the sear, but not so far that it hits the back of the slot. The important part to note is the small gap between the hammer lug, and the slot in the body. That is where the damage occurs if the cocking rod is set too short.  When the bolt position is set using the cocking rod, this is the result:  The problem is that the cocking rod isn't what is stopping the bolt, it's the hammer lug slamming into the body of the gun. In the past two or three years, I have seen over a dozen guns with the rear of the hammer lug slot mushroomed out, and sticking into the lower tube of the gun. This causes inconsistency at best as the hammer hangs up on the protrusion, and it can jam the hammer in the lower tube at worst. You should also note that if you are using an open faces, or cup faced venturi bolt, being able to see the top edge of the bolt in the feed tube means NOTHING AT ALL. In either case, the ball can, and will roll back into the face of the bolt. So, how do you check to make sure you aren't beating the hell out of your body? First, you have to make sure the pump arm is long enough. If the back block touches the body of the gun when the gun is gassed up, the pump arm is too short. You can either unscrew the back block from the pump arm by a turn, or unscrew the ram shaft from the pump to make the assembly longer. Turn the back block is a bit easier, but adjusting the length by the ram threads is more precise. You want a gap of about 1/16" when the gun is gassed up. You should note that the distance between the block and the body will be different when the gun is under pressure because the bumper in the ram will be compressed slightly by the pressure in it. Always do a final check with the gun gassed up. If the bolt is sticking past the back wall of the feed tube, take out the cocking rod, and see if it clears. If it does, then the cocking rod is too short. If it doesn't, then the pump arm needs to be adjusted Pull the back block all the way back and hold it there. Now, reach down, and try to pull the cocking rod farther back. If it moves back a little, then your hammer lug isn't hitting the body. If the cocking rod doesn't move back any more, then it is limiting the travel of the back block, and abusing the body at the same time. To correctly set the cocking rod, de-gas the gun, and slowly pull the back block back. You will hear a slight click when the hammer lug clears the sear. You want to be able to pull the back block about 1/16" to 1/8" past that point before the throw of the ram stops the travel. |

Your IP Address is: 3.19.56.45

Copyright © 2024 Moody Paintball.